Why this guide exists

China is one of the world’s deepest supply bases for sports optics, and it can absolutely produce hunting binoculars that feel premium in the hand and hold up in the field. The catch is that “premium” is rarely decided by a single spec line like ED glass or fully multi-coated lenses. Returns happen because of the quiet failures: inconsistent collimation, focus that stiffens in cold weather, coatings that flare in backlight, or waterproofing that doesn’t survive real abuse.

This article is a buyer’s framework. It’s designed to help you define a hunting binocular correctly, evaluate suppliers with evidence (not marketing claims), and build a production plan that protects quality at scale—especially if you sell online, where return rates can wipe out your margin.

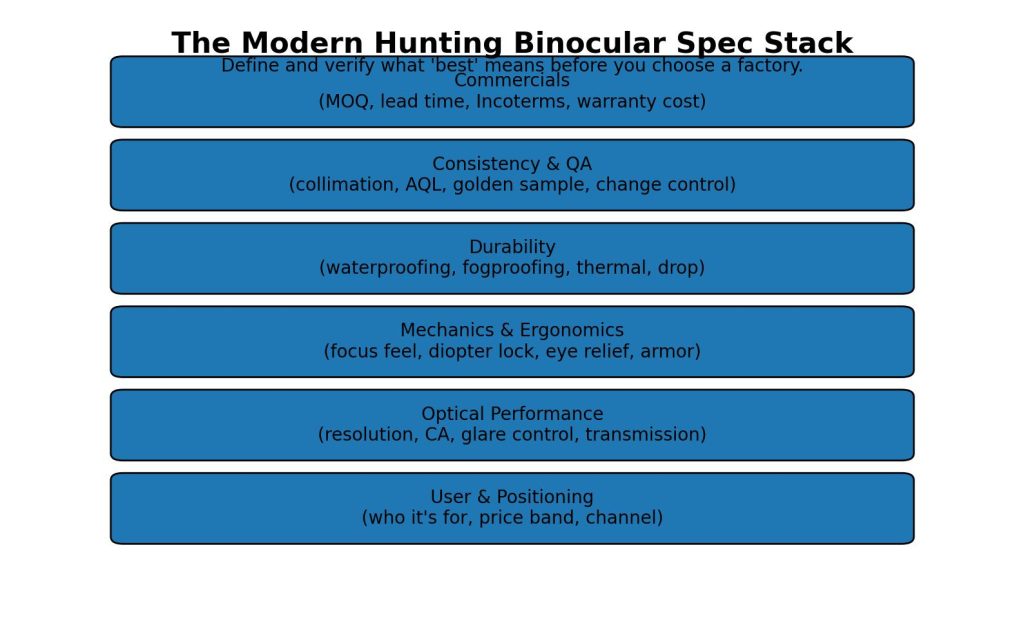

8 Points for Sourcing High-Performance Hunting Binoculars

1) Start with the hunter, not the glass

Before you compare factories, get brutally specific about where and how the binocular will be used. Hunting optics are not one-size-fits-all, and a well-defined use case is the fastest way to avoid a spec sheet that looks great but disappoints in the field.

Define your scenario using a short brief:

- Terrain and light: timber, open country, mountains, coastal humidity; day vs dawn/dusk bias

- Carry style: all-day chest harness vs pack carry; glove use; one-hand focus behavior

- Priority order: low-light performance, glare control, edge sharpness, weight, durability, price

- Channel reality: e-commerce needs lower defect/return rates; retail needs stronger in-hand ‘wow’

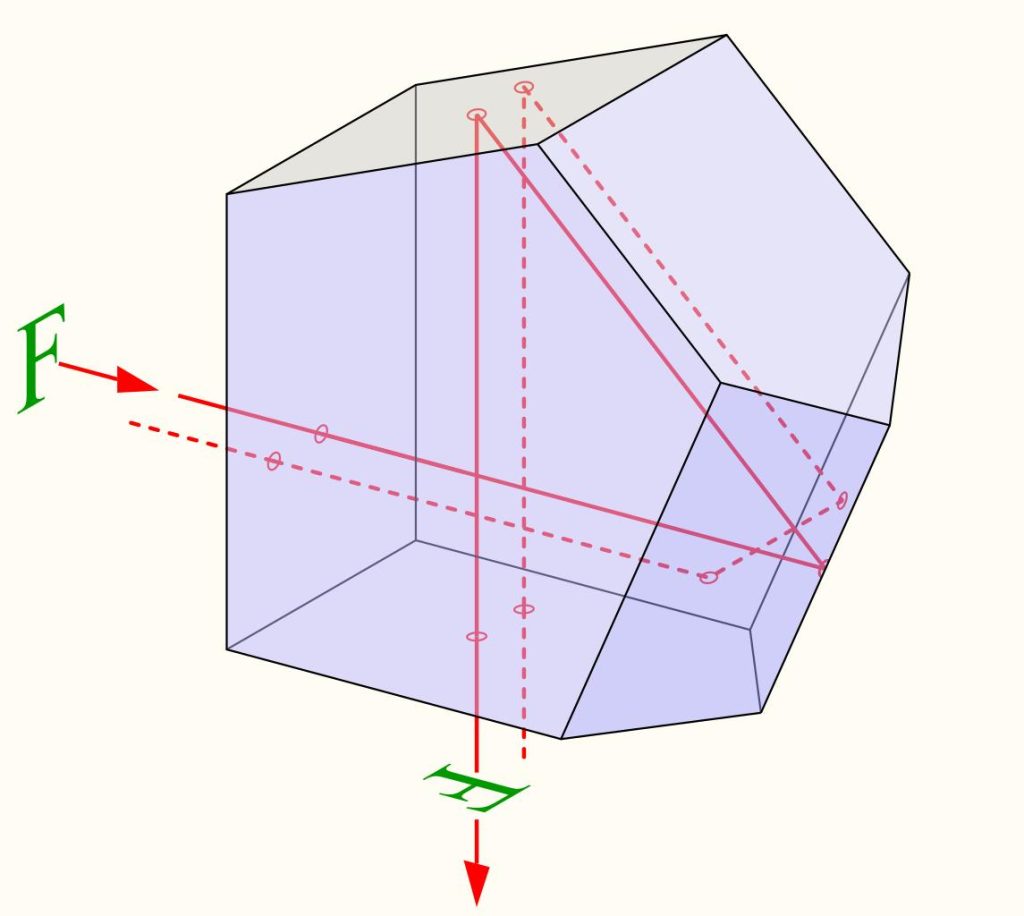

2) Optical performance: move beyond buzzwords

“ED” and “FMC” are useful indicators, but they don’t guarantee the viewing experience. The buying mistake is assuming a label equals a result. Instead, ask for testable outcomes and compare samples side-by-side under the lighting hunters actually face.

The optical questions that separate good from great:

- Resolution and micro-contrast: how much fine detail is preserved at distance

- Chromatic aberration control: high-contrast edges (branches, ridge lines) reveal color fringing

- Glare and ghosting: backlit scenes expose stray light and internal reflections

- Field sharpness and distortion: edge softness, field curvature, and the ‘rolling ball’ effect

- Transmission in low light: practical dusk performance (not just a number on a sheet)

If your supplier can’t explain how they measure or verify these characteristics, treat “premium” claims as unproven.

3) Mechanics and ergonomics: the return-rate killers

Two binoculars can look identical on paper and feel radically different in use. Mechanical execution affects comfort, speed, and—most importantly—consistency over time.

Key mechanical items to evaluate on samples:

- Focus feel: smoothness, backlash, and how it behaves in cold weather

- Diopter adjustment: firmness and whether it locks or drifts during carry

- Eyecups: positive click stops, durability, and comfort with glasses

- Hinge tension: holds IPD setting without loosening over months

- Armor and grip: wet-hand traction, long-term tackiness, and seam quality

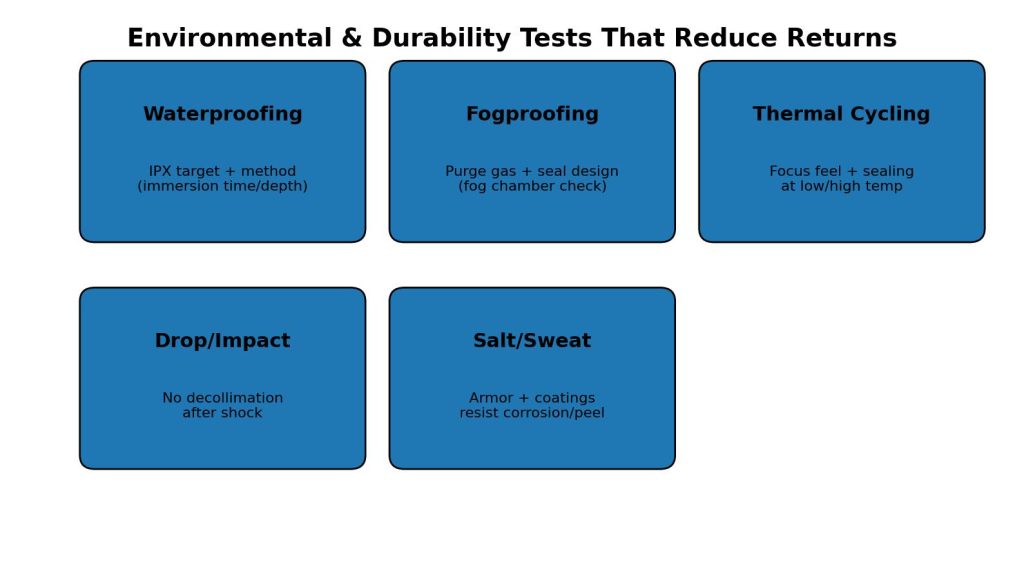

4) Durability is a system, not a checkbox

Waterproof and fogproof claims are only meaningful if the manufacturer can show how they test, how often they test, and what their pass/fail criteria are. The same applies to impact resistance and thermal stability.

A practical rule: if the binocular is marketed for serious outdoor use, demand repeatable test methods and batch-level evidence—not a one-time demo video.

5) Consistency and QA: what makes a supplier truly “trusted”

Premium hunting binoculars fail quietly when alignment drifts. Even small collimation issues can cause eye strain, headaches, and returns that are hard to diagnose through customer support.

A trusted manufacturer isn’t the one with the longest feature list—it’s the one who can produce the same experience across thousands of units.

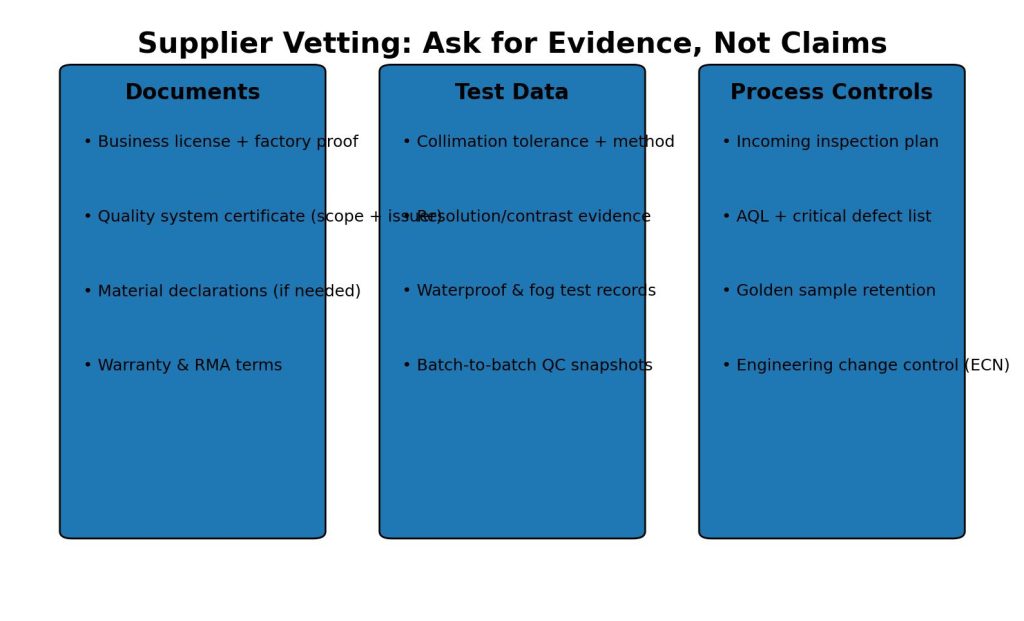

What to require in writing:

- AQL plan with a clear ‘critical defect’ list (collimation, water ingress, focus failure, internal dust)

- Golden sample retention and matching rules for mass production

- Engineering change control (no substitution of materials/coatings without written approval)

- Traceability (batch/lot identification that links to QC records)

6) Compliance, labeling, and logistics: the details that delay launches

For many brands, the biggest surprise isn’t optical performance—it’s shipment readiness. Confirm early what your channel requires: labeling, barcode placement, country-of-origin marking, packaging warnings, and any material declarations for your target region (for example, RoHS/REACH requests from EU-oriented customers).

Operational checks that save time later:

- Packaging and accessory list locked before production (caps, case, strap/harness, cloth, manuals)

- Incoterms aligned to your risk tolerance (EXW vs FOB vs DDP)

- Spare parts plan for eyecups, caps, and straps—small pieces drive a lot of support tickets

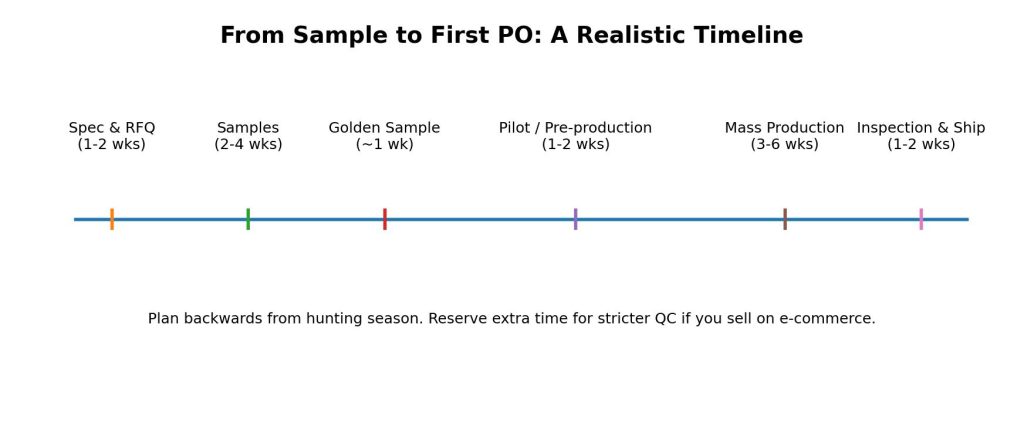

- Seasonal capacity planning: hunting season demand spikes can stretch lead times

7) A supplier-vetting checklist you can actually use

If you only take one thing from this guide, take this: great suppliers answer with proof. They provide specific documents, clear test methods, and process controls that match the level of product you want to sell.

8) Your RFQ should read like a test plan

Most RFQs fail because they describe features but don’t define acceptance. Treat your RFQ as the first draft of your quality agreement.

RFQ elements that reduce ambiguity:

- Model target (8×42 / 10×42) and weight goal

- Optical requirements (prism type, phase correction, coating expectations)

- Environmental targets (waterproofing method, purge gas, thermal range expectations)

- QC expectations (collimation verification, AQL, sampling method, records retention)

- Commercial terms (MOQ tiers, lead time, inspection windows, warranty responsibility)

Finally

Chinese manufacturers can build hunting binoculars that compete confidently in the global market. The brands that win are the ones that define ‘best’ in field terms, validate performance with repeatable tests, and lock quality with process controls before volume.

If you want fewer returns and stronger reviews, invest in the unglamorous work: collimation standards, environmental verification, golden samples, and change control. That’s what turns a promising sample into a reliable product line.