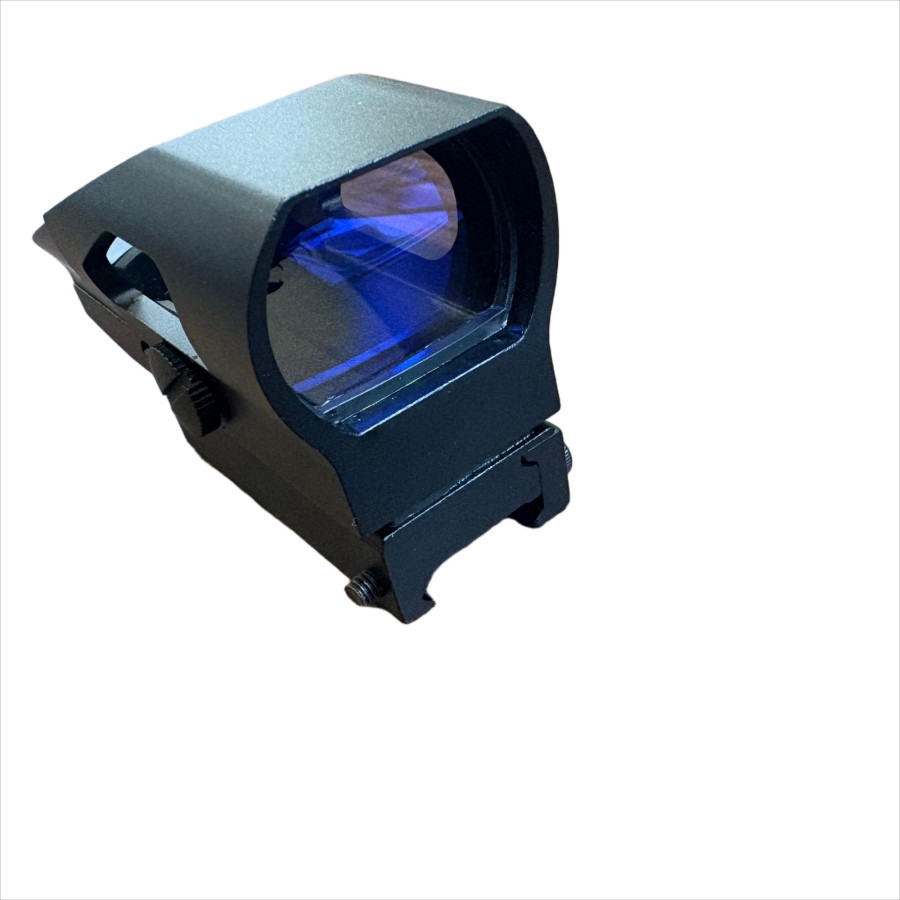

Shotgun Red Dot Sight

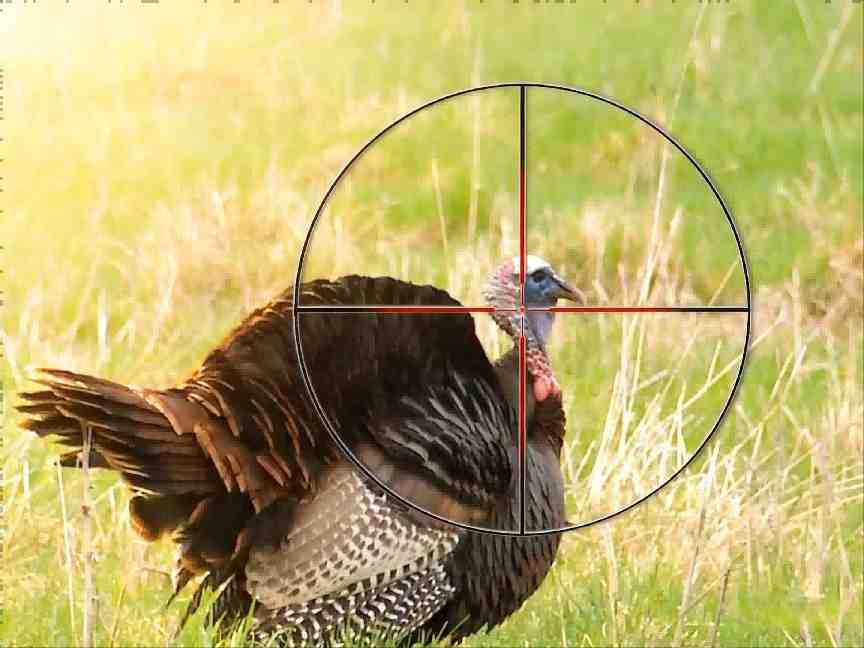

General design requirements: The use of red dot sights on shotguns is becoming increasingly common, especially in tactical applications (such as law enforcement and home defense) and in hunting scenarios (turkey, deer, etc.). Shotgun red dot sights must be designed to handle heavy recoil and strong vibration. The recoil impulse of a 12-gauge shotgun is very severe, so the sight must have exceptional shock and vibration resistance to maintain zero. Only red dot sights that have been specially reinforced are typically rated for shotgun use.

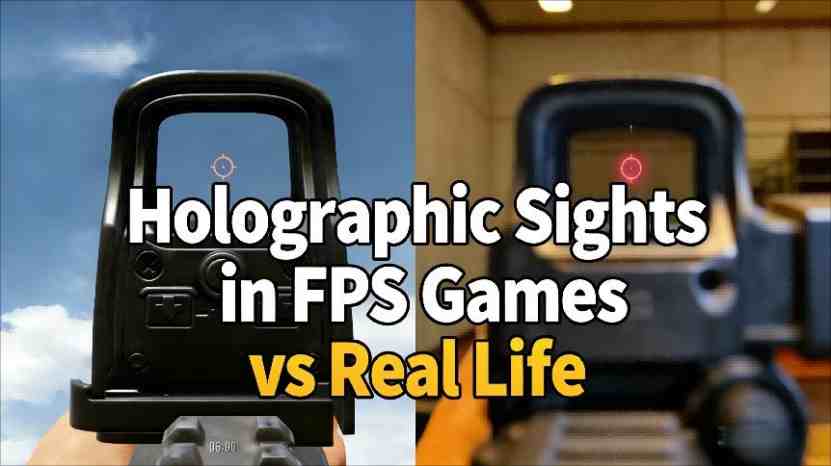

At the same time, shotgun shooting often involves fast, both-eyes-open engagement, so the red dot should provide a wide field of view and intuitive aiming to allow rapid target acquisition under pressure. Although holographic sights perform very well in this regard, offering true binocular vision and fast target acquisition, their high cost limits adoption; within FORESEEN OPTICS’ production volume, holographic sights account for less than 1%. Parallax correction is also important for shotgun red dots, because shotguns are used at relatively short distances and users expect the dot to closely match the point of impact at close range. This requires minimal parallax at common distances such as 25–50 meters. High-quality red dot sights can approximate “unlimited eye relief and parallax-free” performance in this range.

Structure and mounting: Shotguns are commonly mounted in two ways: top rail mounting and barrel rib mounting. Tactical shotguns and some hunting shotguns have a Picatinny rail on top of the receiver, allowing direct installation of standard red dots. Traditional hunting shotguns often lack rails and instead require modification or dedicated rib-clamp red dot mounts. These designs must accommodate different rib widths and typically use adjustable clamps or shims for proper fit. Co-witness is also a consideration: shotguns usually use a bead sight, and some users prefer the red dot to align with or sit slightly above the original bead so mechanical aiming remains usable in emergencies. This requires careful selection of mounting height, and some manufacturers offer risers or adjustable-height mounts to meet this need. Since shotguns are often used outdoors and in wooded environments, strong resistance to rain and impact is essential, and the sight surface should use matte, anti-reflective finishes to avoid alerting game. For semi-automatic shotguns, ejection port clearance must also be considered to ensure the red dot does not interfere with cycling or operation.

Market trends: In recent years, two clear trends have emerged for shotgun red dot sights. The first is lighter weight and smaller size, to reduce impact on firearm balance and handling. The second is specialization, with designs optimized specifically for shotgun use. Some brands request very large MOA dot options for fast, close-range shooting. While large dots may be too coarse for precision rifles, they allow much faster target acquisition on shotguns. Another trend is pairing red dots with magnifiers; when using slugs for longer-range targets, red dot plus 3× magnifier combinations are being accepted by some hunters to improve hit probability. Overall, shotgun red dots are shifting from “general-purpose optics adapted for use” to sights purpose-built for shotguns, including stronger internal structures and optical calibration matched to typical shotgun distances.

FORESEEN manufacturing and support advantages: FORESEEN has a deep understanding of the specific demands of shotgun platforms. In our designs, we apply dedicated reinforcement for heavy recoil, such as dual anti-loosening lens retention structures and vibration-damping compounds on circuit boards, ensuring stability under 12-gauge recoil. We can customize shotgun-specific mounting solutions, including rib-clamp bases with adjustable width mechanisms to secure the sight firmly on ribs of different sizes, or quick-detach rail mounts that allow users to rapidly remove optics for storage or use of iron sights.

FORESEEN specializes in producing high-strength yet lightweight structures, using aerospace-grade aluminum and weight-reduction designs to maintain durability without affecting shotgun balance. We also adjust aiming dot specifications based on customer needs, offering smaller MOA dots for tactical users seeking precision and larger dots or rings for hunters prioritizing speed. Through cooperation with our coating suppliers, we can provide matte, low-reflectivity finishes and camouflage coatings to reduce visibility in tactical or hunting environments. In terms of quality control, shotgun red dots undergo high-intensity vibration table testing and live-fire testing before shipment, ensuring each batch is ready for direct installation and maintains zero. FORESEEN is committed to providing professional-grade shotgun red dot sights for B-end customers, enabling end users to trust their optics even under the harshest recoil and environmental conditions.

FORESEEN Shotgun Red Dot Sight Series

Can’t Find the Product You Want? We Can Customize It!

POPULAR SCOPES & SIGHTS FOR YOU

FORESEEN One-stop Service,

Save Worry, Save Trouble, Save Cost

Stock Combination Delivery

Solution Matching

Development from Scratch

Quick Customization

Deep Customization

Choose us, and make your brand even greater

Blog

Continuous investment in technology and product upgrades is our primary means of helping

clients maintain their market competitiveness.