This is a “forked path,” not just simple product competition.

In the first two days of the 2026 SHOT Show, I kept hearing two completely different sets of keywords at nearly every handgun red dot sight booth.

At the booths of EOTech, Aimpoint, and some law enforcement system integrators, what I heard was:

- “We don’t want to worry about rain, mud, sweat, or oil anymore.”

- “A red dot shouldn’t fail because of environmental conditions.”

Meanwhile, in areas with Shield Sights, competitive shooters, and training organizations, the messages were:

- “The bigger the window, the faster I can acquire the dot.”

- “I don’t want the housing to block my view.”

It was through this repeated contrast that I gradually realized: handgun red dots have clearly split into two technical paths.

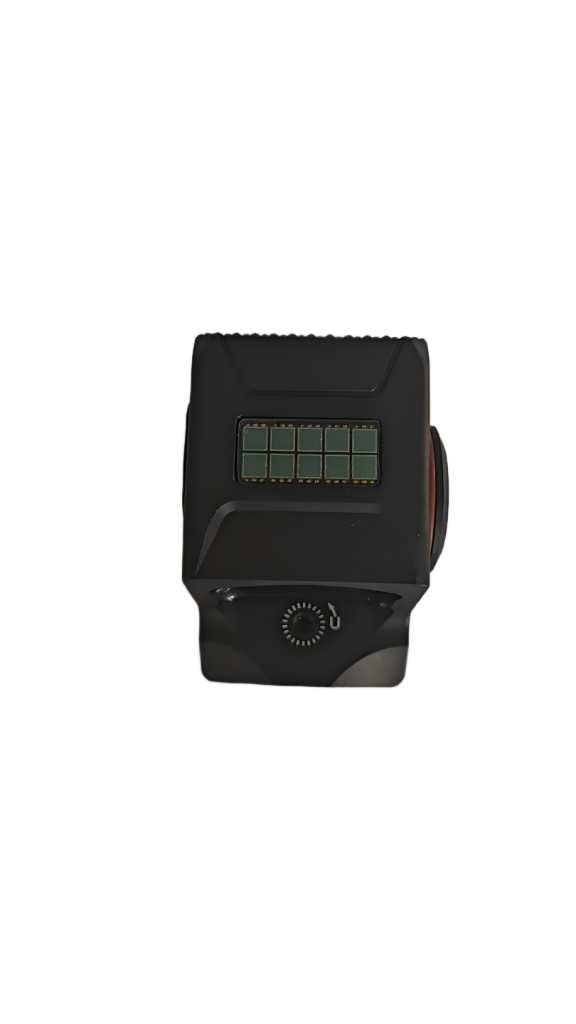

- Mailbox / Closed Emitter: EOTech EFLX-CE is a typical example.

- Ultra-Window / OMSx Style: Shield Sights OMSx is a typical example.

This isn’t about “which is more advanced,” but rather what I’ve always said:

The scenario is redefining the technical criteria.

At the EOTech booth: everything revolved around “environmental failure”

The first time I really paid attention to the EOTech EFLX-CE, it wasn’t because of its specs, but because an engineer said to me:

“The starting point for this product was simple — a red dot shouldn’t become a burden just because it’s dirty or wet.”

What they kept emphasizing wasn’t how big the window was, but rather:

- Whether the LED is fully sealed

- Whether the electronics are exposed

- Whether the red dot can maintain a predictable operating state under long-term high humidity, high salt, and high contamination conditions

For them, full enclosure isn’t a style — it’s a risk management strategy.

At the Shield Sights booth: the discussion always starts with the “window”

When I moved over to the Shield Sights booth, the atmosphere was almost completely different.

The moment I picked up the OMSx, a competitive shooter next to me said:“Notice how the housing almost disappears.”

The Shield team’s discussion focused on the same points:

- What the human eye dislikes most during dynamic scanning

- How housing obstruction affects dot acquisition speed

- Why they are willing to accept structural complexity just to maximize the window

Here, the red dot is treated as part of the visual system, not as an electronic component that needs special protection.

Why does this kind of “split” exist? — The answers I got from on-site conversations

After several informal discussions, I gradually grouped user needs into two very typical “use models.”

Model A: Uncontrolled environment + uncontrollable maintenance

This is the most common set of demands I heard from law enforcement, duty users, and outdoor users.

- What they care about is not:Whether the window is the biggest

- Whether the dot can be 0.1 seconds faster

But rather:

- Does it still light up in the rain?

- Can it still be used after getting into mud?

- Will anything go wrong if the lens isn’t cleaned for a year?

Under this model, the logic of the fully enclosed approach is very consistent:

If the environment is uncontrollable, use structure to lock the uncertainty away.

Model B: Extreme motion + dense targets

Among competitive shooters and high-frequency trainers, the focus is almost completely different.

- They care more about:Whether the dot enters the field of view immediately when the gun is raised

- Whether the dot frequently “runs out of the window” during rapid, continuous fire

- Whether the housing interferes with situational awareness

Under this model, the advantages of products like the OMSx are very direct and obvious.

As one shooter put it very plainly:“The bigger the window, the less time I spend ‘looking for the dot.’”

Six technical dimensions: the real trade-offs I observed

This part is based on repeated side-by-side comparisons and hands-on time at the show.

Across six core technical dimensions, I try to stay faithful to two things each time:

what I heard on site, and how I personally interpret those views.

Optical axis height and tolerance of the field of view

As I repeatedly raised the pistol and aimed at different booths, one feeling became very clear:

- Window size determines whether you have to intentionally search for the dot.

- Optical axis height determines whether your draw and presentation feel natural.

On the EFLX-CE, I could clearly feel that EOTech put real effort into keeping the height down.

Even though it’s a closed emitter design, I didn’t get the strong sensation that “the dot is sitting too high.”With the OMSx, however, the experience was completely different.

The first time I brought the gun up, I almost had an illusion:“The dot doesn’t feel like it’s inside a frame — it feels like it’s floating directly in my vision.”

This comes from the combined effect of window area, housing obstruction ratio, and visual guidance.

My takeaway is:

- High-frequency, dynamic shooting: OMSx-style designs have a very clear advantage.

- Standardized technique + harsh environments: as long as the window is large enough, the gap with closed designs can be largely closed through training.

Mounting method: direct mounting is becoming a “hidden threshold”

At the 2026 SHOT Show, I could clearly feel a trend taking shape:

whether closed or open, everyone is pushing hard toward lower height and direct mounting. I even saw a crowd constantly gathered around the Aimpoint COA display — something I’ll cover in another article.

In conversations with engineers, a few keywords kept coming up:

- Interface layers

- Load transfer paths

- Tolerance stack-up

To me, this is no longer just about “ease of installation.”

It’s really about one deeper question:

Is the red dot an add-on, or is it part of the firearm system?

Whether it’s the EFLX-CE’s compromises for multi-footprint compatibility, or the OMSx’s insistence on ultra-low direct mounting, both are choices made under different commercial and engineering constraints.

Impact resistance and sealing: where the split is the sharpest

This was the area with the strongest disagreement on the show floor.

On the closed-emitter side, almost every discussion eventually came down to one sentence:

“The LED should not be exposed.”

On the open-emitter side, I repeatedly heard the opposite view:

“We’ve been using open designs for years — they’re not that fragile.”

My interpretation is:

- Fully enclosed designs are buying failure-probability management.

- Ultra-window designs are buying performance certainty.

These two values don’t actually conflict — they simply serve different users and different scenarios.

Battery life and electronic architecture: controllability vs minimalism

This is a very typical difference in engineering philosophy.

On the EOTech side, what I kept hearing was:

- Side-loading battery compartment

- Manual brightness control

- Lock, sleep, and shake-awake functions

On the Shield side, the answer was much simpler:

“We don’t want users to have to think about these things.”

Automatic brightness, fewer buttons, fewer failure points — this is a very clear minimalist path.

My personal conclusion is:

- System-managed environments: controllability matters more.

- High-frequency training or competition: minimalism can actually be more reliable.

Lens coatings and anti-reflection: far more important than the spec sheet

This is a dimension you can only truly appreciate by repeatedly looking into the optics on site — under show lighting and from different angles.

The transparency of the OMSx is among the best I’ve seen in micro red dots.

And although the EFLX-CE uses a dual-window structure, in real-world viewing it didn’t give me any obvious color shift or distracting glare. This once again confirms a simple truth:

The real differences are often not on the spec sheet, but in the optical details.

Weight and size: deciding whether you’re willing to carry it every day

Among concealed-carry users, the phrase I heard most often was:

“It’s not about whether it works — it’s about whether I want to carry it every day.”

Closed-emitter designs do pay a penalty in overall size and volume, while more streamlined, open designs like the OMSx have a natural advantage here.

At the same time, some duty users told me just as clearly:

“I’d rather it be a bit bigger, as long as it doesn’t give me problems.”

My overall judgment: not opposition, but maturity

After walking the entire SHOT Show, I actually see this as a very positive signal.

Handgun red dots are no longer chasing a single “right answer.” Instead, they are beginning to diverge around real-world use scenarios.

- Fully enclosed designs focus on solving “what I least want to happen.”

- Ultra-window designs focus on maximizing “the performance I need most.”

If I had to sum it up in one sentence:

This is a shift from spec-driven competition to system- and scenario-driven competition.

And to me, this very split is a clear sign that the industry is moving toward true maturity.

Three key focus directions for FORESEEN OPTICS over the next 12–24 months

- Closed-emitter optics are likely to become part of the core lineup for major brands. For us, the focus is on continuing to explore better solutions tailored to small and mid-sized brands — specifically, whether next-generation designs can further expand the window and reduce overall height without sacrificing reliability.

- A key question is whether open-emitter optics can introduce more “semi-enclosed” protection concepts without giving up their window advantages — for example, improved sealing around the emitter area while maintaining an unobstructed visual experience.

- Will direct-mount interfaces truly become a cross-brand engineering consensus? Will more handgun manufacturers, like Glock, define their own mounting standards similar to the Aimpoint COA? We’re watching closely and looking forward to entirely new models of collaboration.

These three directions may ultimately define what handgun red dots look like in 2027–2028.