Based on the experience of FORESEEN OPTICS’ engineering team—a small group of six led by CEO Michael—that has worked on over 100 red dot sight projects, we have summarized a complete process for new red dot sight brands to communicate with Chinese factories and build a product line from scratch. The following will walk you step by step through the key stages and important considerations, from market research to product launch.

1. Define Market Demand and Product Positioning

Before starting customization, we assume you have done thorough market research and decided to launch a red dot sight product line. Based on this, it’s important to further identify the greatest common denominator of your target customers’ needs. In other words, figure out which product categories and models existing customers are most likely to accept, and which ones will grow fastest among new customer groups. This helps clarify your product line positioning and prioritize development. For example, if market research shows strong demand for micro pistol red dots, but your existing users prefer a certain classic rifle red dot model, these two product types might become the core of your product line.

At the same time, it’s wise to learn from successful products in the industry. Over 50% of brands decide to make their red dot sights by using designs that people already like and then they make some changes so it fits with what their brand is about. By looking at competing products and overall market trends, you can make a product that people will like and that is also a little different from what is already out there. In other words, prioritizing red dot models that are already proven popular in the market will help you quickly gain recognition from your target customers.

Conducting benchmark analysis on top-selling models can guide new brands in their product development. Many brands reference well-known red dots like Aimpoint or Holosun and then customize them with their own features, combining market acceptance with differentiation.

2. Define Red Dot Specifications by Firearm Platform

At FORESEEN OPTICS, we classify red dot sights by firearm platform, and we recommend starting the same way—by deciding which platforms your product line is meant for, such as pistols, rifles, shotguns, or crossbows.

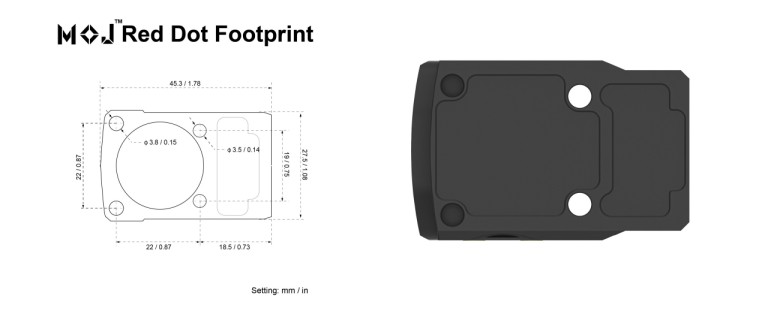

Different platforms have different requirements for the size of the red dot, the installation interface, and the recoil resistance. For example, micro red dots made for pistol slides need to be small and light, but still tough enough to handle handgun recoil. Shotgun red dots usually need a bigger window and a more specific mounting setup. This step quickly defines the basic specifications and mounting method of the red dot, because the overall structure and manufacturing process are largely driven by the firearm platform it is designed for. As FORESEEN OPTICS often points out, firearm platforms vary widely in size and recoil behavior, and only by matching the optic to the correct platform can you ensure a sound design and reliable performance.

3. Focus on the Key Performance Factors of a Red Dot Sight

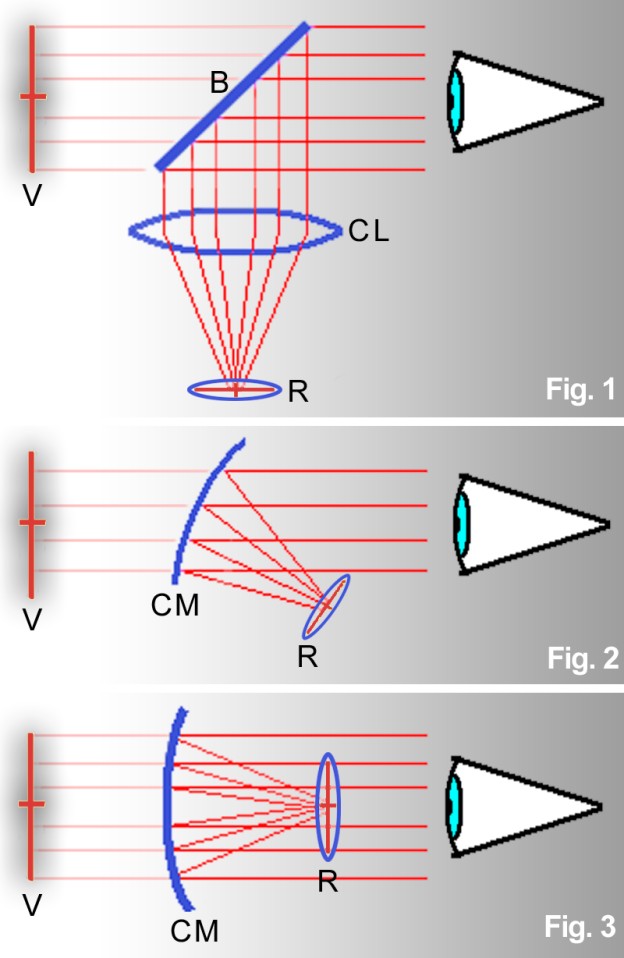

Once the platform is defined, the next step is to look at how a red dot sight actually works and identify the key factors that affect its performance. These factors largely determine the optical design, core components, and overall cost of the product. A well-designed red dot sight should let the shooter stay focused on the target, with a dot that is easy to see and an optic that does not get in the way of the sight picture. To achieve this, several areas deserve close attention:

● Aiming reference and parallax

Good red dot sights are really important because they have quality lenses and special coatings. These help keep the dot right where it should be when you look at it from angles. The view is also very clear. To make this happen the lenses have to be shaped right or lined up perfectly. If they are not the picture you see will be distorted. It is true that better optics cost money. They make it easier to aim and feel more comfortable when you are using them. Red dot sights that are quality are worth it because they help you aim more consistently.

● Dot type and size

The dot is made by projecting light onto a partially reflective lens. Simple designs usually have a hole or a mask to make the dot. This way is not expensive. It makes the dot not so bright and the battery does not last very long, usually less than 1,000 hours. Higher-end designs let the LED form the dot directly, giving precise shapes, multiple reticle options, and battery life over 50,000 hours. These designs are more expensive so you have to think about what you want your product to do. For instance, if you need multiple reticle patterns, the advanced design is worth it; if a single simple dot is enough, the traditional design is okay and it costs less.

● Brightness control and power

Brightness is something that matters when it comes to these things. Some of these dots can adjust the brightness on their own depending on the light around you and save power when not in use. Some models have panels and a battery. This means that sunlight can power the dot most of the time and extend battery life beyond 50,000 hours. For example, in FORESEEN OPTICS designs, a solar panel is integrated on the top of the optic and paired with an intelligent control chip that prioritizes solar power in bright conditions and automatically manages brightness. These features improve performance, but they also make the red dot more expensive. So you have to think about what people’re willing to pay for the red dot.

● Strength and protection

Red dots also need to be tough. Depending on what kind of gun you have the red dot has to be able to handle things like shock and vibration and water or dust. Some big guns can be really rough on the dot with impacts that are, over 2,000G, so the housing needs strong materials (commonly 6061 or 7075 aluminum with T6 heat treatment), enough wall thickness, and internal support. Water resistance depends on the seals and the coatings that are used. The expensive red dots or the ones that are used by professionals usually have to meet stricter standards.

Altogether, these factors set the core performance of a red dot and how much it costs. Not every feature has to be top-of-the-line—going overboard can raise cost without making the product more popular. A practical approach is the 80/20 rule: use proven solutions for 80% of the design to keep it reliable, and add improvements to 20% areas to make your product stand out. This way, performance stays solid, and your red dot gets its own character.

4. First Contact: Confirm Platform and Core Specs

When you first talk to a factory—like FORESEEN OPTICS—the focus should be on confirming the firearm platform and the core specifications of your red dot sight. Typically, Foreseen Optics will ask you which platform your red dot sight will be used on and your key requirements (Do you need magnification? What size window do you want? How tall should the sight be? What size dot are you looking for? Any special features?) When you are the customer it is very helpful to let the factory know which specifications are really important and cannot be changed, which ones can be a little different and still be okay and which ones are not as important so the factory can give you their ideas. This way the factory can look at the products they already make and find ones that match what you need.

If the factory already has a design that meets most of your needs, that’s usually the fastest route. They can pick a mature design that’s close in window size, appearance, or color, which can drastically shorten development time. FORESEEN OPTICS, for example, offers a “design matching” service that screens over 500 existing models to find the closest match to your specs. You would then only need to tweak details like reticle style or color to quickly get a private-label product. If there isn’t a ready-made match, another approach is to provide the factory with a competitor model you want to benchmark. You could point to a popular brand and say, “We’d like something similar.” Experienced ODMs like FORESEEN OPTICS can use the specifications of that product to develop a fully matching or very similar solution. They call this their “from scratch” service: you provide a reference product, and they deliver a similar design with your custom upgrades. This is a practical shortcut for new brands, letting you leverage proven ideas while adding your own improvements.

Whichever approach you take, the goal of the first conversation is simple: get a direction fast. Either lock in an existing platform to save time and cost, or choose a benchmark product to clearly define the development target. At the same time, discussing which specs are rigid and which are flexible gives the factory clear guidance for design decisions.

5. Look for Differentiated Innovation

It is easy to copy what is already popular when you enter the markert, but we strongly recommend stepping further and adding innovation and differentiation to your product. This means you should talk to the facory about what new features or improvements can be added to an existing design. This will make your product stand out. Now it is time to think about the pain points that users have with dot sights. Identify where users feel current red dot sights fall short or are inconvenient to use, then share the most common issues with the factory. This gives them clear direction on where meaningful upgrades can be made to the design making it special and unique, to your brand the red dot sights.

The 80/20 approach promoted by FORESEEN OPTICS works especially well here: keep 80% of the design proven and stable, and focus the remaining 20% on targeted upgrades. For example, a lot of dots do not work well at night. If your users hunt or operate at night, you should think about adding one or two ultra-low brightness settings that work with night vision. Another example is water resistance. if similar products on the market do not keep water out well, you can upgrade your prodcut to an IPX7 or higher rating. This will clearly set your product apart. Features like Shake Awake (motion-activated power saving) are also worth considering. It turns the optic off when it’s idle and instantly turns it back on at the last brightness setting when it’s moved. If competing products do not have Shake Awake you can ask the factory to add it to your dot. This will make your red dot stand out from others. In short, using the factory’s R&D capabilities and combining them with real user feedback allows your copy-based procuct better than the original.

It’s also worth noting that experienced factories are usually open to these ideas—and often already have the technology ready. For example, FORESEEN OPTICS has standard and upgraded solutions for core technologies such as solar-assisted power, automatic brightness control, and narrow-band coatings. Once you raise a requirement, the factory can quickly evaluate feasibility and suggest an implementation path. So don’t miss the chance to make your product different—bring your ideas to the table and discuss them openly.

6. Product Line Planning: Entry, Mid-Tier, and Flagship Models

After several rounds of discussion with the factory, you figure out the balance between cost, features, and performance. Then you will usually end up with a solid base design. Next, you need to think about how to make multiple versions of this design for different types of users—from entry-level buyers to high-end customers. In practice, this means using the same platform and adjusting certain optical specs or non-core features to create an entry model, a mid-tier model, and a flagship model. This kind of tiered lineup makes it much easier to cover the market at different price points. During testing, samples from different tiers can be given to users with different preferences, helping you collect broader feedback. When the product launches, multiple versions also attract more attention and improve overall conversion.

It is important to be clear that different configurations do not mean offering a low-quality product to entry level users. What we want to focus is to keep core performance reliable across all versions, while adding or removing features in a planned way. For example, an entry model might not have features like solar-assisted power or night vision modes so that we can keep the price down. But it should still perform well in everyday use. A flagship model, on the other hand, can include all the upgrades and best materials to support a high-end brand image. This “one platform, multiple configurations” approach has proven to be a sustainable product line structure. As long as each tier has clearly defined user experience goals, and manufacturing consistency and quality control are maintained, the lineup can grow steadily over time.

In short, covering the widest range of use cases with the fewest SKUs is a smart way to launch new products. Based on FORESEEN OPTICS’ experience, starting with user scenarios and demand levels—and then assigning clear roles to a small number of key specs—allows you to build a product matrix that is both lean and complete. For new brands especially, this approach helps you cover core market needs with limited development resources, while ensuring each model has enough volume to support quality and reputation.

7. Sample Development and First-Round Testing

Once the design direction is confirmed, the next step is sample production and testing. Usually, it’s best to start by testing samples that already exist. A lot of factories including Foreseen Optics keep samples that they made themselves under their own brand or as basic versions. If one of these samples meets more than 90% of your requirements, especially the core functions, it is a good idea to test it first. The reason is simple. Fully custom samples are expensive, often costing hundreds or even thousands of dollars, and the first custom sample always needs changes. When you are working on projects the first sample is mainly used to see if the factory really gets what you want. It is rarely the final version. If the first custom sample does not even fit the platform properly or work well then spending a lot of money on customization before that point is usually wasted effort.

For this reason, we recommend a cautious approach during the early sample stage:

● Make the most of existing factory samples

As mentioned earlier, choose samples that are close to your target requirements and test those first. FORESEEN OPTICS offers standard samples at wholesale pricing (custom samples excluded), which keeps costs low and allows you to test several models side by side. Shipping is usually paid by the customer. These samples let you check core factors such as dot clarity, adjustment accuracy, and shock resistance, and then organize your feedback for the factory.

● Start custom samples carefully

Only move to fully custom samples if no existing option is close enough. When you do, make sure the customization scope and costs are clearly agreed on in advance. As noted in the FAQ, FORESEEN OPTICS charges separately for custom samples, outside normal wholesale pricing. Because custom samples often require tooling or design changes, costs can be significant. That’s why it’s important to finalize requirements as much as possible during the drawing and design discussion stage, to avoid major changes after the sample is made.

● Focus testing on core functions

When you get the first sample, you should prioritize testing the key performance points. For instance, after you put it on the gun and fire mutiple rounds, does the dot hold zero? Is the window stable? Are the adjustment clicks consistent and correct? At the same time,

It’s worth stressing again that the value of the first sample lies more in what it tells you than in the result itself. Even if it’s not perfect, it shows how well the factory understands your needs and where adjustments are required. This feedback loop sets the direction for further refinement. At FORESEEN OPTICS, customer feedback on initial samples is often used to steadily move toward the ideal design, helping prevent larger issues during mass production.

8. Second-Round Samples and Pre-Production Preparation

If the first-round sample performs well—meaning the red dot mounts correctly on the firearm, holds zero during shooting, and all key functions meet what was discussed—the project can move into a second sample stage or a small pilot run. At this point, there are two common ways to move forward:

Option A: Place a small production order and use first-batch units as final samples

Some experienced new brands choose to place a small trial order (for example, 200–500 units) once the first sample passes basic validation. In this setup, the first units off the production line are used as the final approval samples, followed immediately by completion of the remaining quantity.The main advantage is speed. You avoid paying for another custom sample, and the factory will usually move faster once a formal order is in place. If the factory has solid customization experience, the transition from sampling to mass production is often smooth, allowing the product to reach the market sooner. That said, this approach carries some risk. If the first production units don’t meet expectations, the order may need changes or rework. For this reason, it’s better suited to projects with tight timelines and a high level of confidence in the factory.

Option B: Make a revised sample before placing any order

For a more cautious approach, you can choose to develop a second, improved sample. Issues found in the first sample are corrected, and the updated version is tested again before any production order is placed. This helps ensure the final design is fully confirmed before mass production.The benefit is lower quality risk and clearer control over the final result. The downside is extra time—often several weeks or more—and additional sample costs. Brands working with a Chinese factory for the first time, or those with strict internal procedures, often prefer this route for peace of mind.

Whichever option you choose, this stage is about aligning with the factory on all pre-production details. This includes locking down manufacturing processes (such as surface finishes and part tolerances), defining quality standards (often through a signed specification sheet covering performance targets and test methods), and confirming production timelines.

FORESEEN OPTICS often recommends a pilot production run—a small batch used to verify manufacturing stability before full-scale production. This approach combines elements of both options: it validates the design under real production conditions without committing to a large volume upfront. Once the pilot run is approved, full production can move forward with much lower risk. It’s worth discussing this option with your factory to see if it fits your project.

9. Business Details: MOQ, Payment, and Customization Costs

During the sample development stage, it’s important to discuss key business matters with the factory in advance. Sorting these out early helps avoid misunderstandings when moving into mass production. Key points to cover include:

● Minimum Order Quantity (MOQ)

MOQs vary widely depending on the factory and the product. According to FORESEEN OPTICS’ FAQ, non-custom products typically start at 50–100 units, depending on standard packaging. Custom products usually require 200–1,000 units, depending on the level of customization. You need to confirm the MOQ for your specific project. If your projected order is below MOQ, options include negotiating a small-batch fee or combining orders with other buyers.

● Payment Terms

Most Chinese factories require a 30% deposit, with the balance due before shipment. Payment methods typically include wire transfer (T/T), letters of credit (L/C), or even PayPal. FORESEEN OPTICS also offers credit terms for premium customers, with bank guarantees. Make sure to clarify payment milestones (deposit, sample fee, final balance) and methods to manage your cash flow.

● Warranty

Understanding the factory’s warranty coverage is also crucial. FORESEEN OPTICS provides one-year warranty on standard products, two years for waterproof models, and five years for military-grade products. Warranties usually cover manufacturing defects, with free repair or replacement during the coverage period. Clarifying warranty terms helps you set up your own after-sales policy and define responsibilities in case of batch quality issues.

● Customization Scope and Costs

Different customizations have different MOQs and costs. Typically:Optical customization (special lenses or coatings) is the most complex and may require higher MOQ and development fees. Electronics customization (special LEDs, custom chips) comes next. Structural or appearance customization (new molds for housings) requires enough units to spread mold costs. Color, paint, or logo customization has lower thresholds—usually a few dozen to a few hundred units—and cost is calculated accordingly. Packaging and accessory customization often have the lowest requirements. Many factories, including FORESEEN OPTICS, are willing to produce packaging at cost (EVA cases, blister packs, gift boxes, etc.).

You should ask specifics, for example: How many units for a red dot with special coatings? What is the MOQ and mold cost for a custom housing? How many units for branded packaging? Organizing this information helps plan your overall budget and phase in customization gradually—start with low-threshold changes like logo or color, then invest in exclusive designs once sales grow.

● Production Lead Time

Don’t forget to confirm production and delivery timelines. Non-custom products usually ship within 7–25 days, while custom products may take 25–60 days. If you have a launch schedule, make sure the factory can meet it. You may want to sign a delivery agreement or consider split shipments.

Sorting out these details during the sample stage—and putting them in an LOI or memo—helps prevent disputes later and aligns expectations. FORESEEN OPTICS is experienced in this area, supporting third-party inspection and split shipments to over 50 warehouses worldwide. Take full advantage of these capabilities to keep your supply chain running smoothly.

Finally, maintaining professionalism and patience in business discussions is crucial. International cooperation can involve information gaps and cultural differences, so asking questions, confirming repeatedly, and keeping written records is the most effective approach.

10. Intellectual Property Protection: Patents and Confidentiality

If your red dot sight features deep functional customization or a unique design, you should consider intellectual property protection before launching the product. This usually includes:

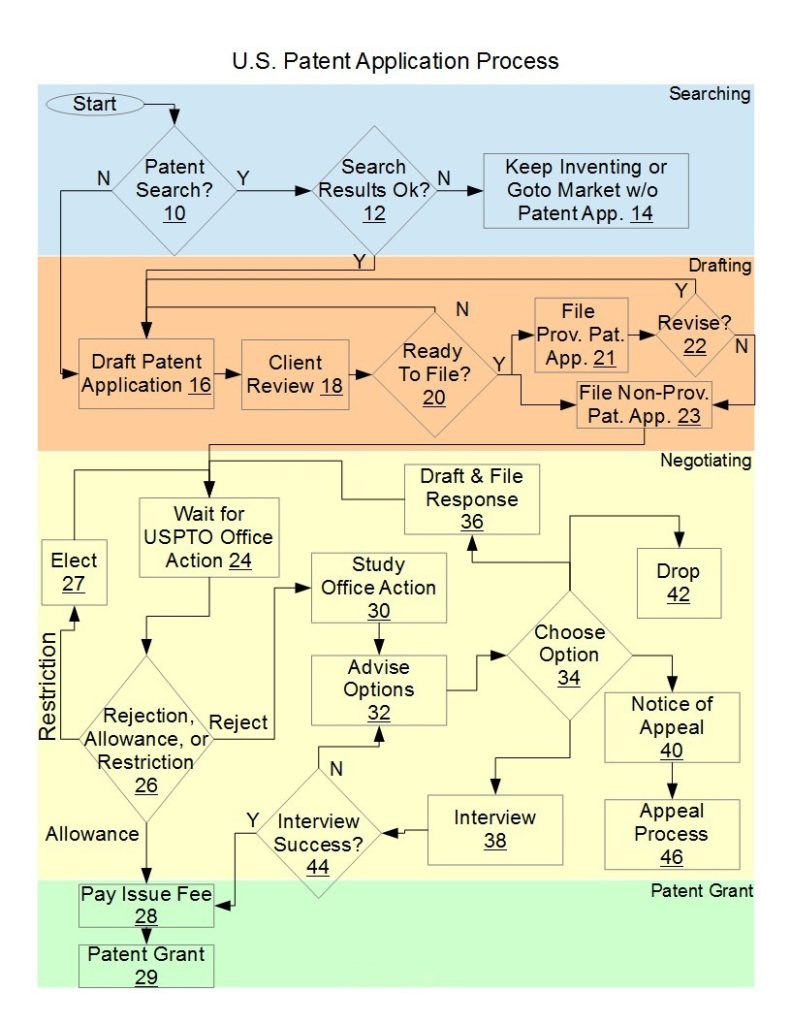

● Patent Applications:

You should talk to an IP attorney to see if your innovation meets the requirements protection for a patent application. If it is a completely new technical solution (such as a unique optical structure, a new mounting interface mechanism, etc.) or an original industrial design (the appearance of a scope), it is recommended to apply for an invention or design patent in the main sales markets. This helps prevent competitors from directly copying your ideas. Also Keep in mind that patent applications take a lot of time and money, so they should be planned as part of your whole project schedule.

● Trademark registration:

You need to make sure your brand name and logo are registered as trademarks in the target market, and also consider registering trademarks in China (if it involves sales in China in the future or to prevent others from impersonating you).

● Non-Disclosure Agreements (NDA):

Signing an NDA with the factory during the development process is a fundamental means of protecting your ideas. This is especially important when your project requires the factory to develop entirely new solutions, and you bear all development costs. In such cases, ownership of intellectual property should be clearly defined. Contract can specify that the factory may not use your unique solutions, molds, software, etc. for other customers, and must keep related technical details confidential. If possible, you can also request exclusivity, meaning the factory only makes that product for your brand. Reputable manufacturers like FORESEEN OPTICS typically respect customers’ intellectual property rights and have experience of providing ODM services to overseas clients and then prohibiting domestic sales. Still, written agreements are an essential safeguard and should not be skipped.

In short, while pursuing innovation, don’t forget to protect its achievements. Patent and confidentiality strategies should move forward alongside product development. This provides a legal safety net once your product is on the market, preventing your hard work from being quickly copied. Factories often offer support and cooperation on this issue, as strong IP practices also reflect their professionalism and long-term credibility.

11. Pre-Production Preparation: Documentation and Packaging

Once you confirm the formal order (whether it’s a direct bulk order or after multiple rounds of sample confirmation), while the factory begins production, one task needs to be carried out simultaneously—preparing the product’s marketing and packaging information. This typically includes:

● Product images and visual assets:

Request or negotiate with the factory to provide high-resolution images and 3D renderings of your products. These will help you to create product catalogs, websites, and promotional materials. Manufacturers like FORESEEN OPTICS often have professional photography equipment and design teams, and can assist with product photography and basic graphic design. Getting these materials early will give your marketing team enough time to design your brand’s unique visual identity (VI).

● Complete specification sheet:

Request a detailed specification sheet from the factory that list all parameters (dimensions, weight, materials, optical performance such as transmittance, exit pupil, field of view, and adjustment range; electronic specifications such as battery life and automatic shutdown time). These figures will be a crucial source of information for your packaging instructions, manuals, and e-commerce product detail pages. FORESEEN OPTICS typically prepares a full spec sheet once the design is finalized, making it easy for customers to use directly.

● Packaging design and accessory confirmation:

If you plan to use custom packaging, this is the right time to start designing the box layout and confirm the dimensions and materials with the factory. At the same time, confirm the list of accessories included with the product (such as tools, batteries, lens covers, cleaning cloths) and the contents of instruction manual. Since packaging and manuals also take time, it’s best to prepare them concurrently with production to avoid situations where “products are produced but packaging hasn’t kept up,” which would disrupt the delivery schedule.

In most cases, material preparation and production will take several weeks. Making full use of this time to complete your marketing assets and packaging allows production and market preparation to move forward at the same time. FORESEEN OPTICS recommends that customres starting this work immediately after placing an order, as providing 3D models and specifications is a simple task for the factory, but crucial for you. With everything ready in advance, you can align product shipment with your market launch, preventing delays in sales due to last-minute photo shoots or packaging modifications.

12. Logistics Planning and Shipment Coordination

During product manufacturing, you also need to plan logistics in advance to ensure that products are exported and delivered smoothly within the expected timeframe. Key points to consider include the following:

● Choosing the right shipping method:

Based on your delivery timeline and budget, decide whether to use air freight, sea freight, or express delivery. Most Chinese manufacturers can support multiple shipping options. For example, FORESEN OPTICS can provide express, air freight, and sea freight solutions according to the customer’s required delivery time, or hand over the goods to your nominated freight forwarder in China. If this is your first time importing, the factory often has partnered freight forwarders that can be introduced. The key is to clarify the shipping method before shipment so that the factory can book space and prepare accordingly.

● Export process and documentation:

Generally, export documents include commercial invoices, packing lists, and bills of lading. Some optoelectronic products may also require certificates of origin or CE/FCC certification documents. You should ask the factory for a clear list of required documents and confirm who is responsible for preparing them (this is mostly the responsibility of the factory’s export department). Factories like FORESEEN OPTICS have extensive export experience and can assist with customs paperwork and, in some cases, destination clearance support. If you have special requirements (such as FDA registration for exports to the United States), make sure to inform the factory as early as possible.

● Coordinating freight forwarders and warehousing:

If you use your own freight forwarder, be sure to provide them with the factory’s contact information and estimated shipping time in advance, and allow them to coordinate pickup directly with the factory. For sea freight, you need to confirm the container loading date and port; for air freight/express, you need to coordinate the pickup time. In one case, FORESEEN OPTICS handled split shipments for a brand, delivering products by express courier to 52 warehouses worldwide. It shows that even complex logistics can be managed with proper coordination.

● Production completion timing:

Ask the factory for an estimated production completion date so you can align logistics planning. Ideally, contact the freight forwarder to book shipping space a week before production completion. If the factory has ready stock or pre-produced inventory, the notification period can be shortened accordingly.

In short, treat logistics as an integral part of the order. This ensures a seamless transition to the shipping process once products pass inspection, preventing inventory buildup due to incomplete documentation or shipping arrangements. It also guarantees that your customers or distributors receive their products on time.

13. Final Quality Check Before Shipment

When production is close to completion, we strongly recommend asking the factory to send you a small batch of final inspection samples for last-round approval. In practice, this is usually around 5 fully packaged, production-ready units.

The reasons for doing this final check yourself are as follows:

● Real firearm testing:

Due to local regulations in China, factories generally cannot test red dot sights using live firearms. Instead, they rely on recoil simulators or impact test rigs to verify shock resistance. While this can catch most structural issues, it’s still not the same as real shooting. By testing the samples on your own firearms, you can fully confirm real-world performance—such as whether the zero holds under different temperatures, ammunition types, and extended firing sessions, and whether any point-of-impact shift occurs over time.

● Full-function and consistency check:

These final samples should be exactly the same as mass production units, including markings, packaging, and accessories. Treat them like a customer would: start from unboxing and check everything. Confirm that all accessories are included, manuals are correct, and packaging is intact. Inspect the optics for cosmetic defects, verify mounting stability, and test all functions—brightness adjustment, auto shut-off, night vision modes, and so on. Just as importantly, compare multiple units side by side to see whether dot brightness, color, and overall performance are consistent. This gives you a clear sense of how stable the mass production quality really is.

● Fix issues before it’s too late:

If you find any problems—no matter how small—report them to the factory immediately and pause shipment if needed. Very often, a minor issue (for example, a battery cap that’s slightly loose) can be corrected quickly and save the entire shipment. Once goods are shipped overseas or delivered to customers, fixing the same issue becomes far more expensive and damaging to your brand. This final checkpoint is your last and most important line of defense.

FORESEEN OPTICS fully supports this kind of final customer-side inspection and will cooperate on adjustments before shipment if needed. In effect, this works like a third-party inspection—only better, because you’re the one doing it. Once you’re fully satisfied with the final samples, you can confidently give the go-ahead for mass shipment, knowing the product quality is well under control.

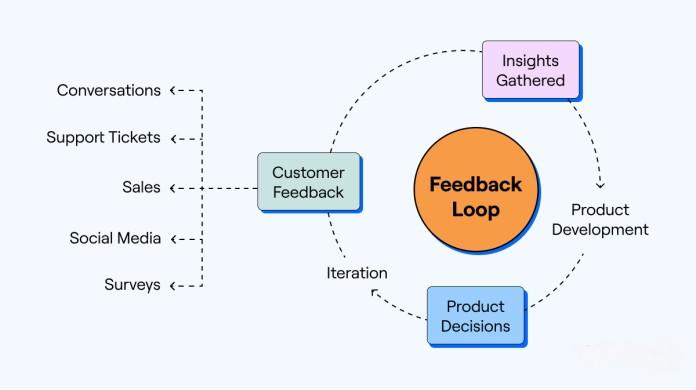

14. Post-Launch Feedback and Product Iteration

Once a product enters the market, the work is far from finished. In practice, this stage marks the beginning of the next improvement cycle. Real user feedback—both positive and negative—is one of the most valuable inputs for future upgrades. Systematically collecting and analyzing this feedback allows brands to refine existing products and plan the next generation more effectively. FORESEEN OPTICS places strong emphasis on post-launch evaluation. For OEM/ODM clients, we often provide follow-up technical suggestions based on market performance, helping products remain competitive over time. From the brand’s perspective, combining real-world user feedback with the factory’s engineering insight is often the most efficient way to drive meaningful improvements.

In practical terms, the following approaches are recommended:

● Establish clear feedback channels:

Use customer service, email, distributors, and social media platforms to encourage users to share their experience. Feedback should be recorded and categorized—for example, optical performance, electronic functions, durability, ergonomics, or exterior design. Over time, recurring issues will become clearly visible.

● Monitor reviews and industry evaluations:

Pay close attention to professional reviews, KOL test reports, and user discussions in forums. These sources often highlight issues that average users may not articulate clearly and provide valuable comparisons with competing products.

● Conduct regular reviews with the factory:

Share summarized market feedback with the manufacturing partner on a regular basis. Experienced ODM factories such as FORESEEN OPTICS can often identify the root causes of reported issues and propose practical design or process improvements. Many of these adjustments can be implemented in subsequent production batches.

● Plan follow-up models proactively:

Based on market feedback, decide whether to introduce minor revisions—such as updated colors, accessories, or small functional refinements—or to initiate development of a next-generation model. In the latter case, the development process should begin early, following the same workflow outlined in this guide, but this time supported by real user data rather than assumptions.In short, product optimization is an ongoing process rather than a one-time effort. Brands that respond quickly to user feedback and continuously refine their products are far more likely to build long-term reputation and customer loyalty. As a manufacturing partner, FORESEEN OPTICS also supports this process by sharing new technical concepts and emerging technologies, helping clients keep their products aligned with evolving market expectations.

15. Maintaining Competitive Advantage Through Ongoing Collaboration

In a highly competitive optics market, long-term success depends not only on your own products, but also on how closely you track competitors and broader industry trends. When competing brands release new red dot sights, it is important to analyze their key selling points and technical highlights, then assess whether similar capabilities should be adopted—or countered—within your own product line. Equally important is maintaining open and regular communication with your manufacturing partner. A strong ODM factory is not just a production supplier, but a development partner. Because they work with multiple brands and platforms, they often have a broader view of emerging technologies, materials, and manufacturing processes. FORESEEN OPTICS, for example, places continuous investment in R&D and process upgrades at the core of its strategy to help clients remain competitive.

Many brands benefit from holding technical review meetings with their factory several times a year. These discussions may cover newly developed technologies such as updated coating processes, more efficient LED components, or smarter electronic features, and whether they can be realistically applied to upcoming products. Over time, improvements in the factory’s technical capability naturally become part of your own competitive edge. In practice, the brand and the factory function as a shared ecosystem. Your commercial success supports the factory’s growth, while the factory’s technical progress directly strengthens your products. Jointly planning long-term product roadmaps and openly sharing market strategies helps establish a stable and mutually beneficial partnership.

Throughout this collaboration, trust and long-term thinking are essential. Once confidentiality or exclusivity agreements are in place, both sides should respect them. Reputable factories understand the value of long-term partnerships and will treat committed clients as strategic collaborators rather than short-term customers. In such a relationship, brands gain faster access to new technologies, while factories benefit from stable demand and meaningful technical challenges. This positive cycle is a strong foundation for sustained competitiveness in the red dot sight market.

In summary, building a successful red dot product line requires careful planning and execution at every stage—from market research and platform selection, through design, sampling, and mass production, to post-launch feedback and continuous iteration. With the support of experienced Chinese red dot sight manufacturers such as FORESEEN OPTICS, even new brands can efficiently move from concept to market, establishing a scalable and competitive product portfolio. We hope this guide serves as a practical reference throughout that journey.