Open Emitter Pistol Red Dot

FORESEEN OPTICS has been manufacturing open-emitter red dot sights since 2003. Our earliest model was a largewindow red dot sight that changed reticle shapes through a mechanical shutter system. It had a very simple structure and used a singlepiece optical lens with singleside coating. This red dot sight is still in production today.

Based on this foundation, we gradually improved our optical lens design and machining capabilities and worked with multiple electronic solution partners, including Samsung Electronics and wellknown LED manufacturers in Taiwan. By 2021, with major breakthroughs in China’s electronics industry, we achieved full domestic sourcing for the entire product system. This significantly reduced the cost of lowpower red dots with features such as motion activation, making advanced red dot sights accessible to more small and midsize brands.

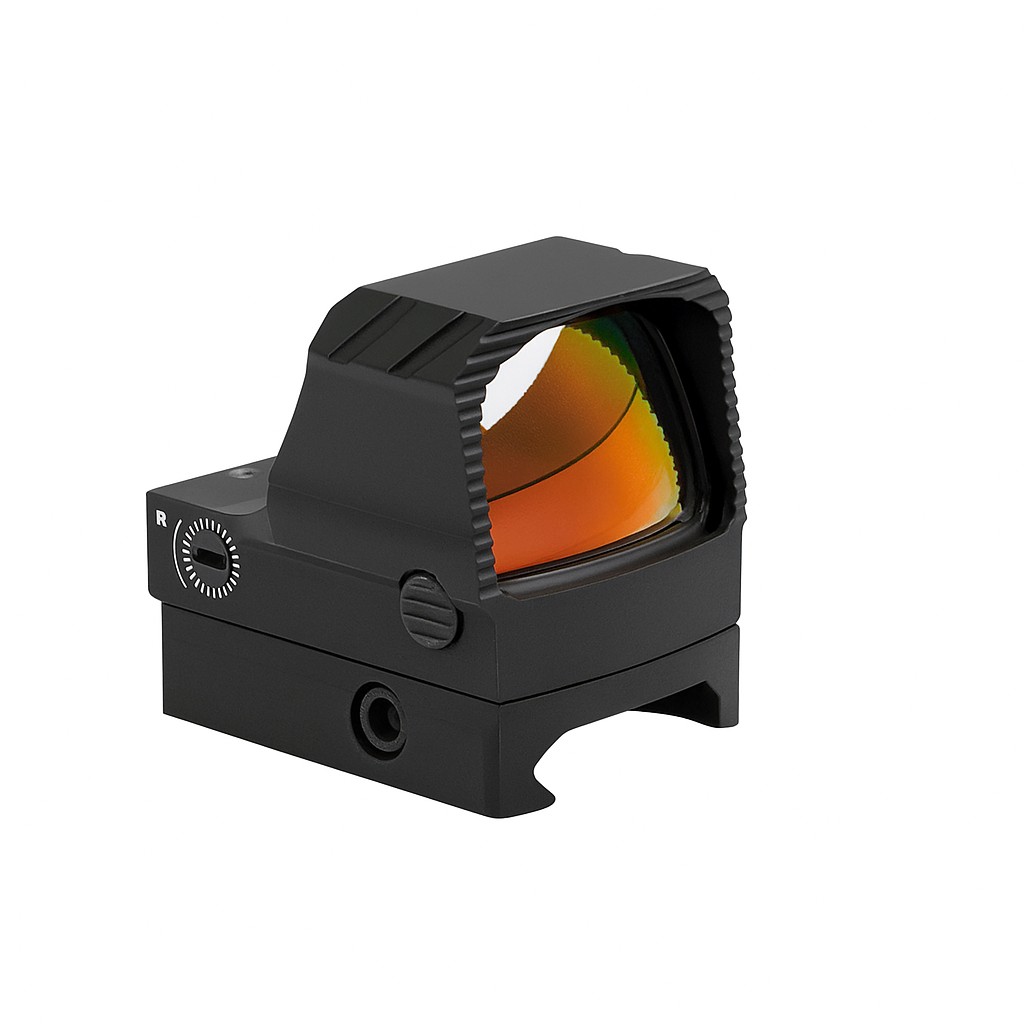

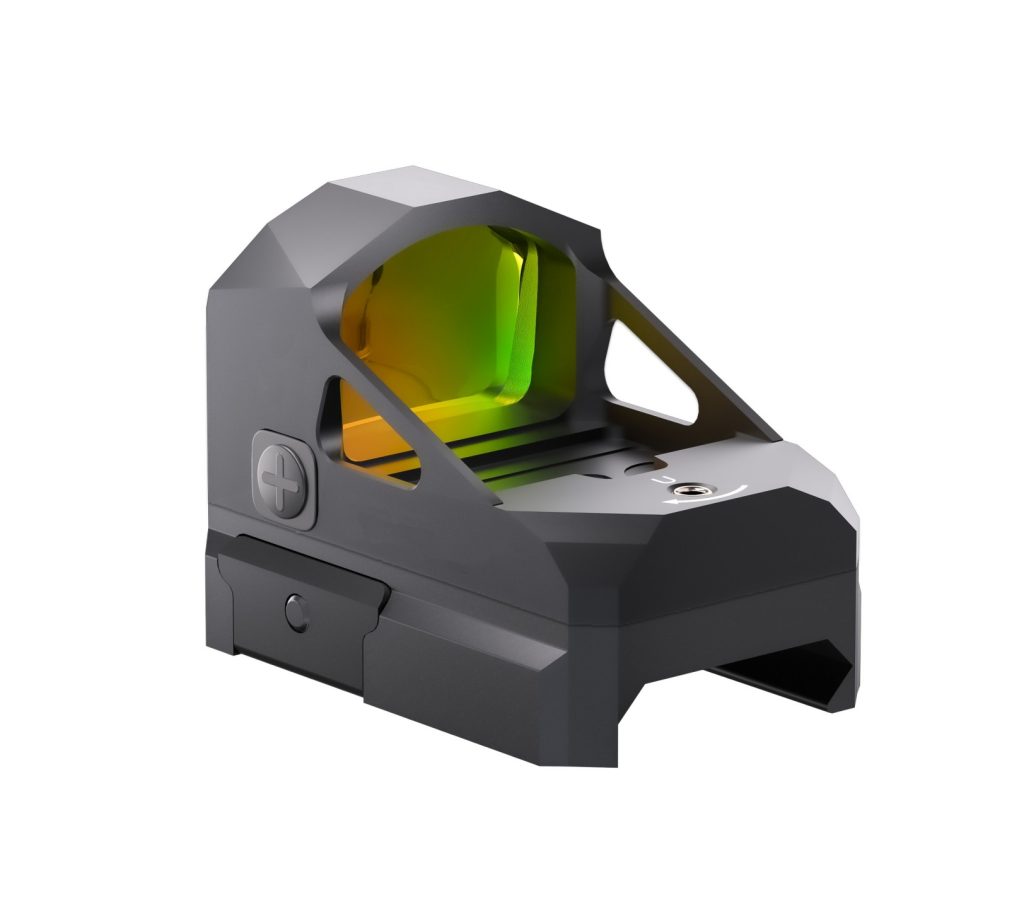

Within the current FORESEEN OPTICS red dot product system, open-emitter pistol red dot sights are the most widely used type for pistol applications. Their core design feature is a lens mounted on a solid base. The LED emitter is usually placed on the opposite side of the lens and hidden inside a small sealed window, projecting the dot directly onto a semireflective lens to form the aiming point.

Because the front hood and enclosed housing are removed, open-emitter designs are generally lighter and offer a larger window view, as there is no front frame blocking the field of view. These red dots typically use a onepiece CNC machined aluminum housing made from 6061 or 7075 aluminum alloy to provide strength and support. Most of our newly launched designs now use 7075 aerospacegrade aluminum, balancing low weight and high strength, and we have already solved previous issues related to uneven anodizing.

For mounting solutions, the Trijicon RMR footprint is the most common choice for open-emitter micro red dots. Through our unique hardalloy external shape design, we protect both the lens and the emitter. Customers often describe the result as “as rugged as an ACOG.” These designs can withstand recoil from pistols, shotguns, and even rifles while maintaining zero, with maximum impact resistance exceeding 3000G.

The open structure above the lens makes the window easy to wipe and clean. In rain or muddy conditions, contaminants can be quickly removed from the lens surface. Open-emitter designs also usually leave space on the top side for integrating additional features such as solar panels. A typical example is Holosun’s open-emitter sights with topmounted Solar Failsafe panels used for auxiliary power and extended runtime. We also offer solutions with solar panels mounted above the window or covering the front of the window.

Performance Challenges:

Because the emitter and optical path are exposed, the main weakness of open-emitter red dots is lower resistance to environmental interference. Rain droplets, dust, snow, or mud entering the emitter recess or sticking to the lens can affect dot visibility. To address this, some of our open-emitter designs include protective shrouds or specially shaped housings to partially shield the emitter. Raised top sections and side wings on certain models are designed to deflect and absorb external forces while reducing the chance of debris falling directly onto the emitter.

Another challenge is waterproofing. Open-emitter red dots usually have slightly lower waterproof ratings because they are not fully sealed, making them less suitable for long-term submersion. Depending on application, our open-emitter models typically range from IP45 to IP67, while some enclosed-emitter models can reach IPX8. In real use, however, our open-emitter red dots still function normally in rain, as long as the lens is cleaned regularly.

Lens cleaning requires special care. Dedicated cleaning fluid, cloths, and brushes should always be used. Since the reflective coatings of open-emitter red dots are exposed, mud and debris can easily adhere to the surface, and improper cleaning may damage the reflective layer. In contrast, enclosed-emitter designs fully seal the diode and reflective surface, offering longer service life.

The third major challenge of open-emitter designs is long-term durability. Without a fully enclosed housing providing overall structural support, strong impacts may cause minor optical path shifts. Aluminum alloys, while strong, still have some structural elasticity and are not as rigid as stainless steel. For this reason, toptier brands often require FORESEEN OPTICS to invest heavily in both design and materials. This includes using high-strength 7075 aluminum, combined with T6 hard anodizing, and optimized housing geometry to ensure zero retention under repeated pistol recoil.

Why develop open-emitter pistol red dot sights with FORESEEN OPTICS?

FORESEEN OPTICS offers fully customized open-emitter pistol red dot development, covering both appearance and performance. In structural design, we focus on optimized shielding. Through carefully designed shapes and lightblocking elements, we reduce the impact of mud and water on the emitter while preserving the wide field of view advantage of open-emitter designs.

Our engineering team is experienced in finite element analysis as well as repeated drop and impact testing, ensuring stability of open-emitter structures under various stress conditions. In materials and manufacturing, we specialize in high-quality aluminum alloy machining and hard anodizing treatments (such as industrystandard T6 coatings) to improve corrosion resistance and wear durability.

In terms of optical performance, FORESEEN OPTICS provides multiple aiming options, including 2 MOA precision dots, ringanddot combinations, and fully customized reticle patterns for major brand customers. Through optimized coatings and precise LED control, we achieve high brightness, high contrast, and clean dot definition.

We also place strong emphasis on power management. Our circuit designs ensure long battery life even with ultracompact batteries, along with reliable motion activation and memory functions. As one of the few red dot manufacturers with an independent electronics development team, we also support custom electronic features for brandexclusive projects. Looking ahead to 2026, we plan to launch more than five new red dot projects with newly developed functions.

As FORESEEN OPTICS continues to reduce costs while maintaining high quality, we look forward to supporting more brands in launching their own open-emitter red dot sights. With strong performance and more accessible pricing, open-emitter red dots continue to demonstrate their long-term value in civilian and competitive shooting markets.

FORESEEN Open Emitter Pistol Red Dot Series

POPULAR RED DOT SIGHT FOR YOU

FORESEEN One-stop Service,

Save Worry, Save Trouble, Save Cost

Stock Combination Delivery

Solution Matching

Development from Scratch

Quick Customization

Deep Customization