An Actionable Framework from Product Positioning to Mass Production for Brands, Product Managers, Procurement, and Engineering Teams

Three Key Takeaways for Product Line Planning

- Start by mapping “scenarios and user groups” in a layered table first. Then decide which of the four main platforms (8×21 / 10×25 / 8×32 / 10×42) cover which needs, instead of starting from magnification.

- Differentiation is not about “just increasing specs.” It’s about writing experience metrics into the specifications: usable field of view (full visible circle), eyeglass compatibility (effective eye relief + eyecup tolerance), and handheld stability (magnification × weight × grip).

- On the manufacturing side, the hardest part isn’t the glass itself—it’s the trade-offs and assembly window between objective size, field of view, eye relief, and prism diameter. Smaller models are especially tricky to get edge performance, eye box, and yield all right at the same time.

Why 8×21 / 10×25 / 8×32 / 10×42: A Core Set Covering Mainstream Needs

These four specifications appear frequently because they form clear steps across portability, brightness, stability, and cost:

- 8×21: Ultra-portable, mainly for short, daytime use like carrying around, travel, or concerts.

- 10×25: Still pocket-sized, but prioritizes “seeing farther,” suitable for city views and light hiking.

- 8×32: Medium-sized, comfortable for long viewing sessions, balancing brightness and size.

- 10×42: Flagship level, optimized for low light and long-distance detail, ideal for birdwatching, hunting, or maritime use.

For brands, the key is to make these four platforms layered without overlapping. It’s not about hitting every spec range, but about ensuring that each layer has a distinct core experience and a clear path for manufacturing.

A Table for the Four Platforms: Positioning, Key Experience Metrics, and Configuration Levers

This table is not a “spec sheet.” It’s a working document used during project planning to align market needs with engineering. The value ranges reflect common industry targets and can be adjusted up or down based on brand positioning.

| Platform | Typical Scenarios | Core Users | Experience Priority | NecessaryConfiguration Levers | Risk Points (Yield-Sensitive) |

| 8×21 | Travel, city sightseeing, concerts | Light users, first-time buyers, gift market | Portability > Ease of use > Center clarity | Low weight / short body; anti-slip grip; fast focus | Short eye relief, prone to black edges; small prism diameter causing dark corners |

| 10×25 | City views, light hiking, entry-level birdwatching | Light users seeking “see farther” | Magnification experience > Stability > Field of view | Don’t make field too narrow; structural rigidity; better coating to control glare | 10× magnification amplifies hand shake; small exit pupil reduces eye position tolerance |

| 8×32 | Birdwatching, nature observation, long daily use | Medium-to-high frequency users; higher proportion of eyeglass wearers | Comfort > Usable field of view > Color / contrast | Effective eye relief ≥15mm (target); clearly stepped eyecups; close-range focus | Large field + long eye relief increases risk for eye box & light cut-off |

| 10×42 | Low light, long-distance detail, maritime, hunting | Professional / heavy users | Resolution & contrast > Low-light > Durability | Large prism diameter; high-grade waterproofing with nitrogen fill; mechanical strength | Multiple assembly & sealing steps; stacked tolerances make collimation difficult |

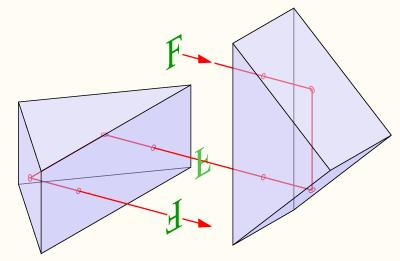

Choosing Roof vs. Porro: How It Affects Differentiation and Cost Curve

With the same magnification and objective size, the choice of optical design changes the shape (whether the binocular is slimmer and straighter), the coating and optical compensation needs (phase correction/reflection control, and the assembly window (collimation and stability).

Planning Recommendations:

- Pocket-sized models (8×21 / 10×25) usually lean toward Roof design, prioritizing shape and weight. However, prism diameter and eye box space must be reserved, otherwise the usable field of view will be cut off.

- Medium and full-size models (8×32 / 10×42) can use either design. For high-end lines, Roof offers a more compact grip and better space for waterproofing. For cost-effective models or to emphasize stereoscopic perception, Porro still has advantages.

- Don’t treat the design type as a selling point by itself. The optical structure is just the path to achieving your experience and cost goals.

1) 8×21: Pocket/Everyday Carry Level (Make “carry” truly portable)

Positioning Layer

- Goal: Truly fit in a pocket or small bag, ready to grab and use. The focus is not on being “the clearest,” but on being “the one users actually want to carry.”

- Typical Price Range: Entry to mid-level; suitable as “series traffic drivers” or gift models.

- Core Competitive Dimensions: Folded size, weight, ease of handling (sensitivity to black edges).

How to Write Differentiated Selling Points (for market and e-commerce)

- “Can hold stably with one hand”: Emphasize grip surface, rubber coating, and anti-slip texture—not just the weight number.

- “See the full circle of the image”: Using “full visible circle” is more effective than nominal field of view (prevents black edge complaints).

- “Durable on the go”: Hinge tension, rubber coating resistance to sweat, and small accessories like lens caps and straps determine repurchase satisfaction.

Specification Recommendations (to include in the “experience metrics” of the requirement sheet)

- Exit pupil around 2.6 mm (8×21); high eye position sensitivity: eyecup steps must be clear, and usable eye box tolerance provided.

- If targeting eyeglass wearers: effective eye relief should be marked as “full field visible with glasses,” otherwise the experience gap is large.

- Prism diameter and eye lens diameter should match the field-of-view target: better to limit the advertised field than to sacrifice edge brightness.

Manufacturing Challenge Checklist (for engineering and quality to lock in early)

- Small prisms / small eye lenses cause vignetting: “bright center, dark edges” is one of the most common complaints.

- Narrow assembly window: slight eccentricity can amplify aberration or black-edge sensitivity; jigs and incoming parts consistency must be stricter.

- Structural strength and hinge life: small size limits wall thickness and thread length, so drop and torque tests should be planned early.

2) 10×25: Pocket Long-Range Level (Higher magnification, stability must be compensated)

Positioning Layer

- Goal: Stay portable, but make “seeing farther” the main purchase driver.

- Typical Price Range: Mainly mid-range; suitable as an upgrade from 8×21 within the same series.

- Core Competitive Dimensions: Perceived hand shake, glare control, and focusing feel.

How to Write Differentiated Selling Points (for market and e-commerce)

- “10× doesn’t mean hard to use”: Use better grip, balance, and anti-slip design to reduce the perceived shake.

- “Clear even against backlight”: Emphasize coatings and stray-light control, instead of vague claims like “fully multi-coated.”

- “Fast focusing”: For frequent switching in city views, focus wheel damping and backlash affect satisfaction more than extreme resolution.

Specification Recommendations (to include as “experience metrics” in the requirement sheet)

- Exit pupil around 2.5 mm (10×25): treat eye box tolerance in the eyepiece design as an acceptance item (e.g., black-edge appearance threshold).

- Field of view should not be too narrow; an overly narrow view cancels out the “long-range” advantage due to poor scanning efficiency.

- Clearly specify minimum focusing distance and diopter adjustment range, as entry-level users rely more on these tangible features.

Manufacturing Challenge Checklist (for engineering and quality to lock in early)

- 10× magnification is more sensitive to collimation; small defects are more likely to cause fatigue or headache complaints.

- Higher magnification is less forgiving at the edges; investment is needed in eyepiece design and machining consistency, not just marketing claims.

- Coating consistency: small-aperture products are prone to batch-to-batch subjective color shifts, so reference standards between batches are required.

3) 8×32: Mid-Size (Comfort over long sessions defines true high-frequency use)

Positioning Layer

- Goal: Make “comfort” measurable: longer eye relief, a larger eye box, and lower viewing fatigue.

- Typical Price Range: Mid to high; suitable as the main volume-driving model that covers the widest user base.

- Core Competitive Dimensions: Eyeglass compatibility, usable field of view, close-focus distance, and overall balance.

How to Write Differentiated Selling Points (for market and e-commerce)

- “Put it on and it just works”: Highlight long eye relief and multi-step eyecups to solve the problem of eyeglass wearers not seeing the full field.

- “High scanning efficiency”: Clearly explain usable field of view and usable edge sharpness; this is more credible than just quoting angles.

- “Comfortable for long sessions”: Weight matters, but balance, grip thickness, and eyecup fit matter more.

Specification Recommendations (to include as “experience metrics” in the requirement sheet)

- Effective eye relief should be designed around eyeglass users (common target ≥15 mm, to be verified with the eyecup structure).

- Close-focus distance can be a differentiation point, as nature observation and indoor exhibition use cases are increasing.

- If choosing a Roof design, the boundaries for phase coating and high-reflective coating should be defined early, otherwise the cost curve can get out of control.

Manufacturing Challenge Checklist (for engineering and quality to lock in early)

- The combination of long eye relief and wide field of view increases the risk of vignetting; system-level validation of apertures, prism size, and eyepiece diameter is required.

- Eyecup assemblies have many parts and long tolerance chains; poor step consistency directly turns into “black edge” or “can’t see the full field” complaints.

- The mid-size platform is best suited for modularization; sharing focus modules, eyecup modules, and bridge assemblies can significantly spread costs.

4) 10×42: Flagship Performance Tier (Low-light and detail demand matching manufacturing and testing)

Positioning Layer

- Goal: The primary tool for professional and heavy users, delivering low-light performance, long-range detail, weather resistance, and long-term reliability.

- Typical Price Range: Mid-high to premium; suitable for building brand image and flagship reputation.

- Core Competitive Dimensions: Resolution and contrast, low-light viewing quality, mechanical stability, and waterproof reliability.

How to Write Differentiated Selling Points (for market and e-commerce)

- “See earlier in low light”: Use exit pupil (4.2 mm) and glare control to explain why the image looks better, not just claim it is “brighter.”

- “Stable long-range detail”: Emphasize mechanical strength and collimation stability under transport, drops, and temperature changes.

- “Professional compatibility”: Details like long eye relief, full-field visibility with glasses, and tripod mounts resonate more with professional users.

Specification Recommendations (to include as “experience metrics” in the requirement sheet)

- Exit pupil around 4.2 mm (10×42): strong brightness advantage, but stray light and ghost reflections still need to be controlled.

- Waterproofing and anti-fogging: sealing level, nitrogen/argon filling, and thermal cycling should be defined as mass-production acceptance criteria.

- Focusing feel and backlash: more noticeable at high magnification; define damping range and focus life-cycle counts.

Manufacturing Challenge Checklist (for engineering and quality to lock in early)

- Many processes and long tolerance chains: stacked tolerances across barrels, bridges, prism seats, and eyepieces directly affect collimation and image quality.

- High rework cost for sealing issues: any repair related to waterproof structures significantly increases unit cost, so first-pass assembly success is critical.

- Testing investment is non-negotiable: establish a full test matrix covering collimation, thermal cycling, drop/vibration, glare, and vignetting.

Overall Manufacturing Challenge Checklist: Turning “Difficult Points” into Manageable Processes and Tests

The checklist below is meant to be reviewed item by item during project kick-off or design review meetings: which items require early validation prototypes, and which must be locked in at the supplier level.

| Challenge | 8×21 | 10×25 | 8×32 | 10×42 |

| Vignetting / Dark Edges (prism size × field × eyepiece) | High | High | Medium–High | Medium |

| Collimation Sensitivity (magnification & structural rigidity) | Medium | High | Medium | High |

| Eyecup / Eye Relief Consistency (eyeglass compatibility) | High | High | High | Medium |

| Stray Light / Glare Control (coatings & internal baffling) | Medium | Medium–High | Medium–High | High |

| Waterproof Sealing & Temperature difference Cycling | Low–Medium | Medium | Medium | High |

| Durability & Mechanical Feel (focus, hinges, backlash) | Medium | Medium | Medium | High |

Platformization Recommendations: Make the Four Specifications a “Reusable Series” Instead of Four Separate Projects

Developing the four platforms from scratch individually leads to high engineering costs and long lead times. A more sustainable approach is to leave differentiation to optics and form factor, while making everything else reusable as modules wherever possible.

Modules That Can Be Prioritized for Platformization:

- Eyecup and eye shield modules: Share step design and material system across platforms to reduce complaints from eyeglass users.

- Focus wheel and drive modules: Standardize damping and backlash criteria to reduce batch-to-batch variation in user experience.

- Coating and internal baffling processes: Establish reusable process windows and inspection benchmarks.

- Test fixtures and collimation procedures: Small-aperture and high-magnification platforms need stable fixtures; investing early saves cost later.

Underlying Benefit of Platformization: Turn “experience” into a “standard” and make yield predictable.

8 Most Common Questions During Project Kick-Off

Q1: Will 8×21 and 10×25 compete with each other?

Not if their purchase motivations are separated: 8×21 is “I want to carry it everywhere,” while 10×25 is “I want to see farther.” Make sure they have clear differences in grip and experience metrics.

Q2: Why does 8×32 often sell better than 10×42?

Because it’s more comfortable for long viewing sessions: lighter, easier to hold, and more tolerant of eye position. Users naturally feel it is “comfortable.”

Q3: Why do small-aperture models often get complaints about “not seeing the full field / black edges”?

Short eye relief + small exit pupil + structural vignetting amplify sensitivity to black edges. The solution lies in eyepiece and eyecup design, not marketing claims.

Q4: Is Roof always more high-end than Porro?

Not necessarily. Roof feels high-end because of a more compact shape and higher manufacturing complexity. Porro can also deliver strong stereoscopic perception and high transmission. The key is which path you take to achieve your cost and experience targets.

Q5: Should we use ED glass?

ED helps control chromatic aberration, but it’s not a cure-all. For pocket-sized models, prioritize usable field, eye relief, and vignetting first. For flagship models like 10×42, ED can be part of the differentiation package.

Q6: Why do prototypes look great, but mass production gets lower reviews?

Prototypes are often hand-picked or manually fine-tuned. Mass production success depends on process windows: fixtures, incoming material consistency, collimation procedures, coating batch control, and measurable acceptance standards.

Q7: How do we write “experience” into the requirement sheet?

Make “what you can see” measurable: full field visible with glasses, vignetting level, glare level, collimation tolerance, focus backlash, and life-cycle counts.

Q8: If we can only make two models, which should we start with?

Most brands start with 8×32 (main volume driver) + 10×42 (brand image & professional). For travel or gift-focused channels, 8×21 + 10×25 are more suitable.

Suggestions: Cover the Most Scenarios with the Fewest SKUs, and Secure Both Yield and Reputation

8×21 / 10×25 / 8×32 / 10×42 are not just “parameter combinations,” but a manageable product ladder. As long as you clearly define experience metrics at each level and turn manufacturing challenges into concrete processes and test standards, these four platforms can form a sustainable backbone for your product line.